our members

Daniel Scott

Team Manager, Design Engineer

Eloise Geddes

Portfolio & Social Media Manager

Charles Cheung

Lead Design Engineer

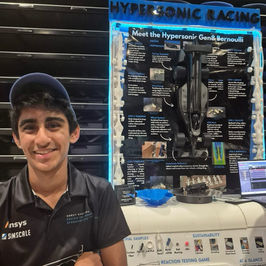

Dhruv Khurana

Design Engineer, Sponsorship Manager

Laila Sellers

Graphic Designer, Portfolio Manager

Aanya Desai

Social Media Manager

Taking Action

At MW Hypersonic racing, we stand by the principle that actions speaks louder than words. We understand real progress comes not from what we say, but what we do, turning ideas into action. Inspired by Magorium, a Singapore based charity, our team has used a similar process to recycle plastic at school.

1. collection

The first step was collecting plastic bottles, these could be milk cartons, shampoo bottles etc. The whole team joined in gathering plastic from home, saving it from bins and therefore the ocean. It must be washed and sanitised before moving onto the next step in the process

4. Illistrator drawings

When the plastic sheets were ready, it was time to begin the exciting process of designing products. As a team we brainstormed a wide range of ideas. Not only team merch but also practical, functional items to be used in everyday life. Each concept was drawn onto Adobe Illustrator with precision and creativity.

2. SHREDDING

Once the bottles were collected and washed, they were carefully placed one at a time into the shredder, where they were grounded down and transformed into hundreds and hundreds of tiny plastic fragments, reading to be repurposed into new, sustainable products, giving old products new life.

3. formation of plastic sheets

After the plastic bottles were shredded, we placed them into the heat compress to be turned into strong and sturdy hard plastic sheets. We utilised many different colours, in order to create interest in the products we were designing.

5. laser cutting

When are drawings were ready for cutting, we were a step closer to giving old plastic a new life. The plastic sheets were carefully placed into the laser cutter, where intricate lines from our drawings were etched with precision, bringing life and functionality to our designs

5. FINISHED products

When the laser cutter was done, we carefully assembled 3D products and sanded keychain edges to perfection. We are incredibly proud of this initiative and hope to build on it in the future - organising community beach clean-ups to collect plastic and inspiring younger students through hands-on learning.